Cement producer Tanga Cement Public Company Limited (DSE:SIMBA/TCCL) will be able to significantly lower its cost base in 2016, thanks to new kiln line, the Managing Director of TTCL,Reinhardt Swart, explained.

The cost of production of cement was negatively impacted by expensive clinker imports, which will no longer be the case after the commissioning of the Tanga Kiln 2 (TK2), as indicated in the TCCL’s 2015 annual report.

TCCL started TK2 for the first time on the 4th December 2015 and produced the first clinker from the new kiln in December 2015, in accordance with the original project plan.

The new kiln more than doubles TCCL’s production capacity with the new installed clinker production capacity increasing to 1.25m t per year.

The Chairman of TCCL, Lau Masha, explained: “Improving operational efficiency and containing production costs continues to be a major focus for the company… we have spent a lot of money in the last few years so as to ultimately reduce costs and become the most competitive cement producer in the region.”

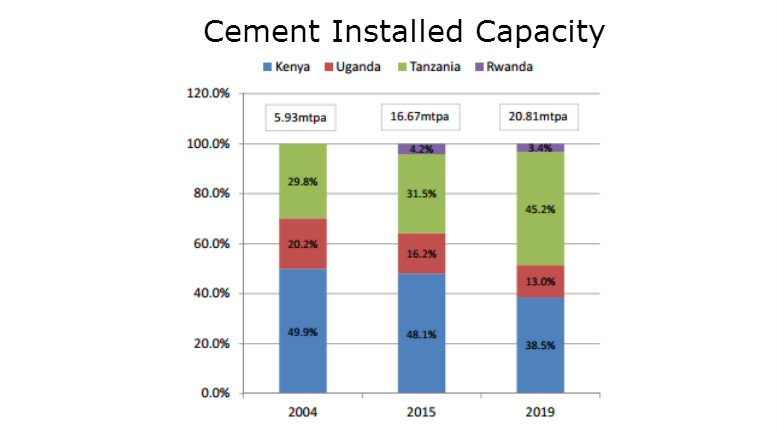

TCCL’s cement production stands at around 1m t per year, while cement production in Tanzania was last estimated at 3m t in 2014 with cement consumption of 3.7m t during the same year.

The average price of cement per ton in Tanzania decreased from USD137 in 2012 to USD123 in 2014 and according to the Standard Investment Bank (SIB), the price is expected to have fallen to USD107 in 2015 and to remain at that level in the next two years.

In Q4 2015 the Dangote group of Tanzania launched its new USD 500 million cement plant in Mtwara district, Tanzania’s south eastern region.